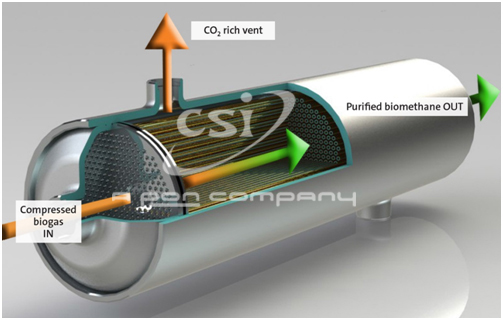

CO2 removal system

CSI works closely with our associates to develop the CO2 removal systems using membrane technology. It will help to remove CO2 & Water vapour from the feed gas. The membrane system is a tried and accepted natural gas treating technology with the distinct advantages in a variety of processing applications. The membranes have become and established technology for CO2 removal since 1981.

Systems performance:

- >90-95% removal CO2

- <2-5% CO2 content in product gas

- Purity ranging from 90-97%

To improve the performance of the CO2 membrane, the system includes pre-treatment which has separate to remove the condensation/oil content from the hydrocarbon gas, coalescing filters to remove solid particulate, particulate filters to remove dust and heaters to provide uniform gas temperature. The vessels for the equipment are designed according to ASME code/ European code based on client requirements.

Our CO2 removal systems will be custom built to suit the customer requirements.

Application:

- Pipeline gas applications

- Biogas or digester gas

- Fuel Gas conditioning

- Methanol Cracking

- Methanol Production

- Bulk removal upstream of an amine plant

Other Mechanical and Process Skids

CSI designs and manufactures other range of Mechanical and Process packages for the Oil & Gas industry

Some of our popular packages include for as follows:

- Closed and Open Drain Pump Skid

- DE oiling and DE sander Skid

- Pressure Reduction Station Skid

- Filtration Skids

- Static API tanks & ASME pressure Vessels

- Shell & Tube Heat Exchanger